Pharmaceutical

Our expertise

-

- Information Technology

- Industrial Internet of Things (IIoT)

- Cloud Computing

- Electronic Batch Record (EBR)

-

Formulation

Formulation is the process in which different chemical substances, including the active drug are combined to produce a final medicinal product.

Eliminating paperwork, reducing errors and maintaining high quality standards will increase the throughput of the plant

-

- • Improve consistency

- • Increase throughput

- • Reduce waste

- • Improve product quality

- • Reduce compliance cost

- • Reduce inventory levels

- • Reduce Cycle time

- • Improve customer service

- • Maximize return on net assets

-

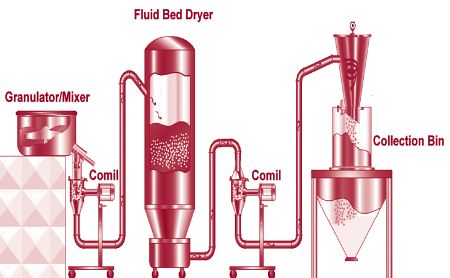

- • Rapid Mixer Granulator

- • Fluid Bed Dryer

- • Blender

- • Vacuum Tray Dryer

- • Tablet Compression

- • Auto Coater

- • Strip Packing

- • Powder Filling

- • CIP/SIP System

-

Active Pharmaceutical Ingredients

API can be defined as the chemicals used to manufacture pharmaceuticals drugs

- • Bulk Chemical: Large volume production & Lower unit cost

- • Fine Chemical: Smaller scale & relatively higher cost

-

Benefit of Automation :

- • Minimize people intervention

- • Maintain accurate and reproducible operating conditions for reaction

- • Integration of multiple operations

-

Manufacturing Execution Systems

- • Paper-based processes are replaced as MES software manages master batch records and electronic batch recording

- • The MES system covers the entire manufacturing process from product dispensing and weighing, tableting and filling of liquids, through to packaging

- • EBR helps ensure the batch documentation is correct and comprehensive, with all processes and specifications enforced

- • Retrieving data from machines or line controllers into the batch record, which allows eliminating error and capturing more data

Chemical

- Sulphur Recovery

- Secondary Brine Processing

- LNG Train

- Conveyor Systems

- Lube Plant

- Hydrogen Plant

- Co2 Plant

- Ammonia Plant

- Fertilizers

- Distillation